The Bearing Inspector is a bench top system for measuring the torque characteristics of anti-friction bearings and bearing assemblies. Contained in the system are a customized computer, monitor and keyboard, and the necessary circuitry for performing a test and processing the results. User-friendly menus enable the operator to rapidly become proficient with the operation of this National Instruments Labview-based system.

torque testing systems

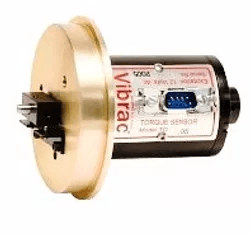

Vibrac® was founded in 1960 and has been designing and manufacturing precision electromechanical torque test equipment for customers whose applications commonly require important torque performance data for improving quality, product reliability and engineering design. Located in Manchester, New Hampshire (USA), Vibrac® manufactures, a broad range of automated and manual precision torque testing systems for accurately measuring torque of numerous types of rotational devices.

PRODUCT INFORMATION

As the industry leader in the precision torque test equipment market, Vibrac continues to develop advanced technological solutions to industrial torque testing problems. Over fifty years of experience in the field of torque measurement has resulted in the development of this patented digital measuring system. The Model 2500 Torque Inspector is an innovative, cost-effective bench top system for measuring the torque characteristics of rotating devices. It has been used to test devices such as fasteners, gas caps, window cranks, medical devices, military components, night vision apparatus, and helicopter links, among numerous others. Easy-to-use programming features enable the user to tailor a test to the requirements of almost any application.

Cap torque testing has been an integral part of the packaging industry’s quality control program for years. Cap torque testing helps prevent consumer complaints from difficult-to-open products, product leakage or spoilage from loose caps during transportation. Many packaging facilities use small, manual desktop models that are inconsistent and non-repeatable due to outside variables. A manual tester’s accuracy is affected by the operator’s physical size and strength as these factors can deform a cap and apply variable torque (variable acceleration), leading to an inaccurate result. Even something as simple as wet hands can cause slippage and affect the accuracy of manual cap testers. The cap inspector series serves the beverage, dairy, pharmaceutical, personal care, cosmetic, consumer product, automotive and chemical industries.

Vibrac’s patented optical torque transducer technology provides a unique method for precise and accurate torque measurement. The durability and reliability of Vibrac’s torque sensors has been demonstrated by the more than 20 years of industrial application in both laboratory and production environments.

The transducers use encoder-type discs to shutter light proportionally to the angular displacement of a torsion bar. This light is then converted by high output photocells into a current that is likewise proportional to the torque.

Visit Partner's Website

Visit Vibrac's website to know more about the company and the complete range of products that serve many industrial fields.

Ask For Specific Item

You can call us or send us a message if you have any technical inquiry or asking about specific item and we will be glad to provide help as soon as possible.